- Products > Milling and sewer rehab robots > Talpa FSR 2060

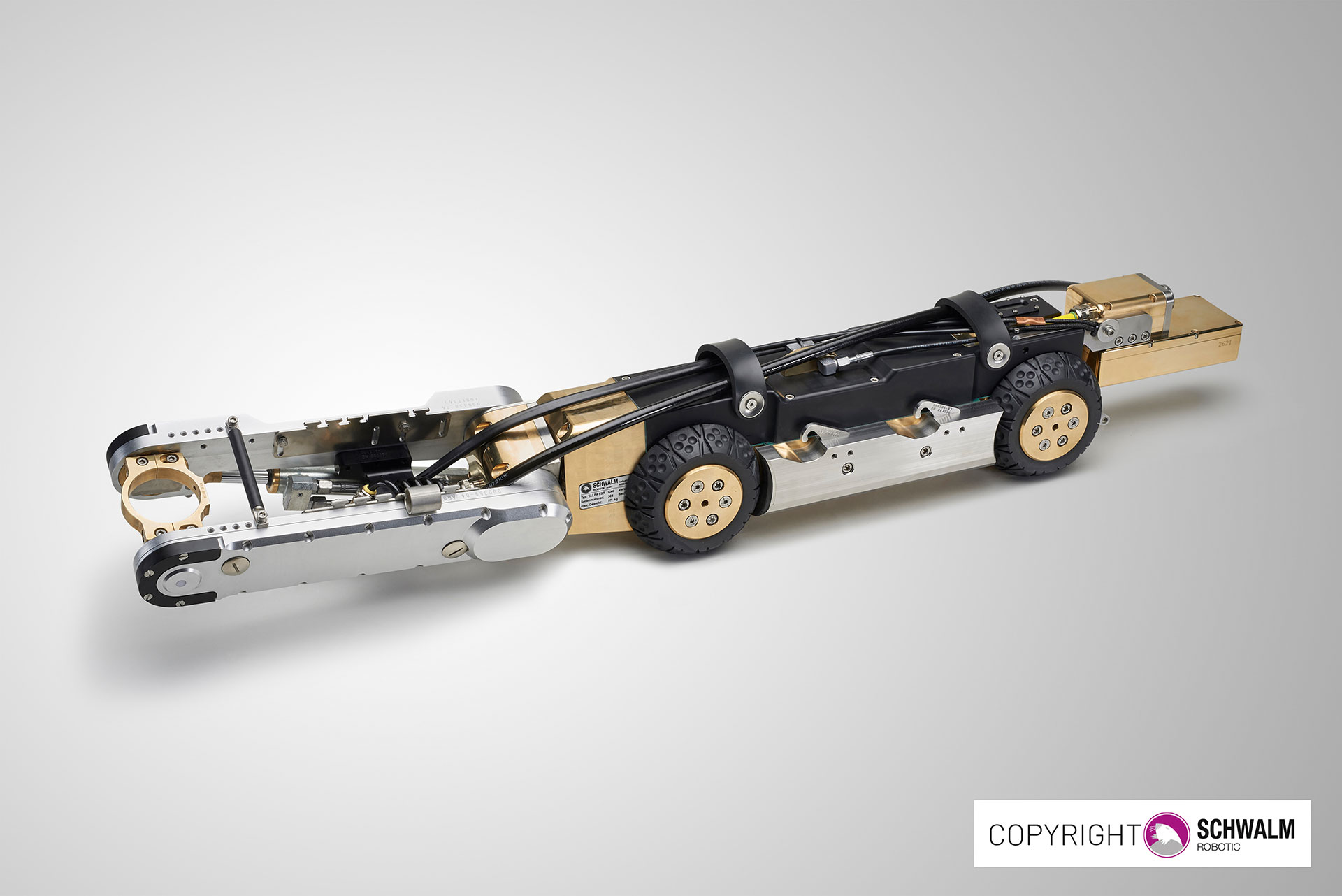

Talpa FSR 2060

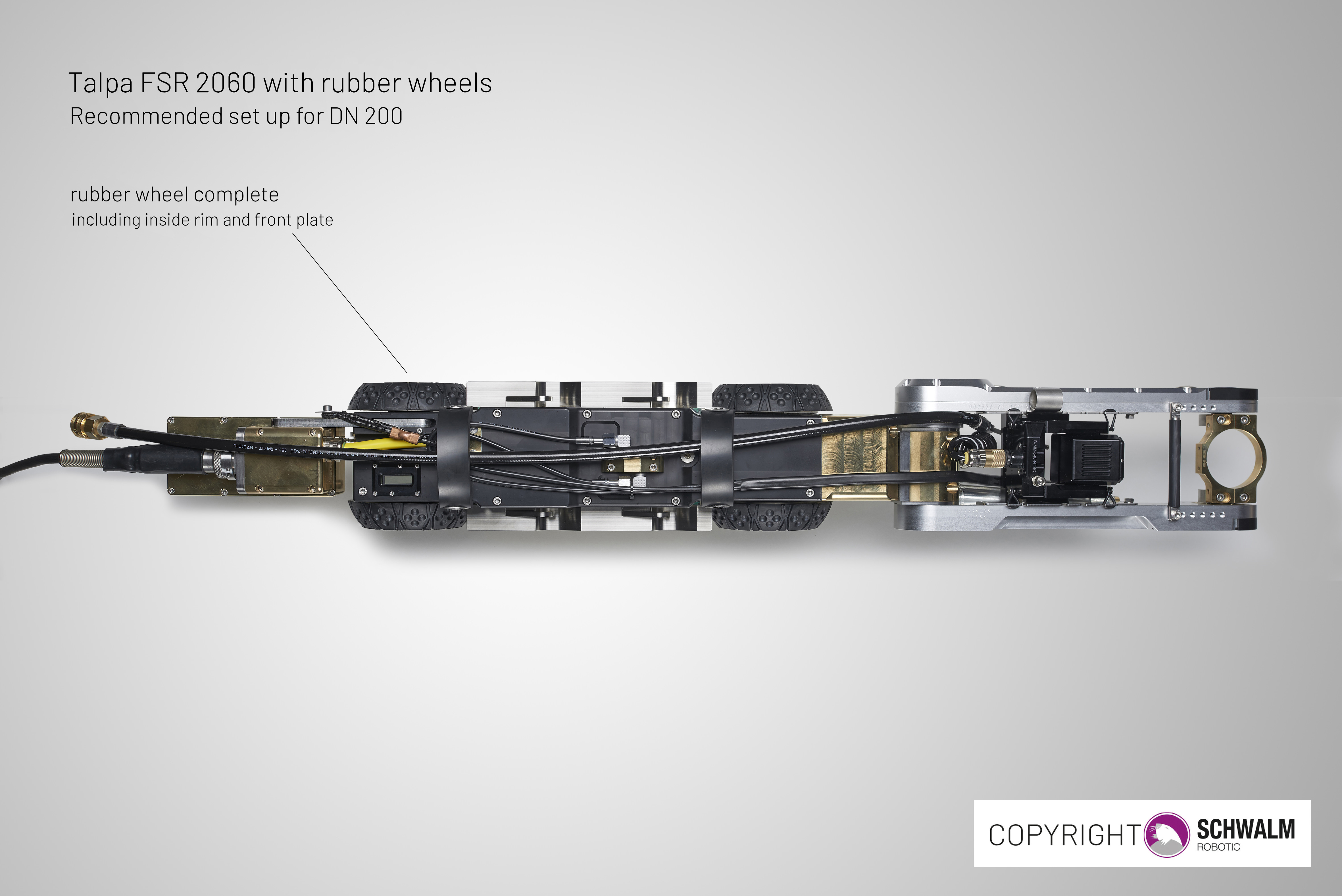

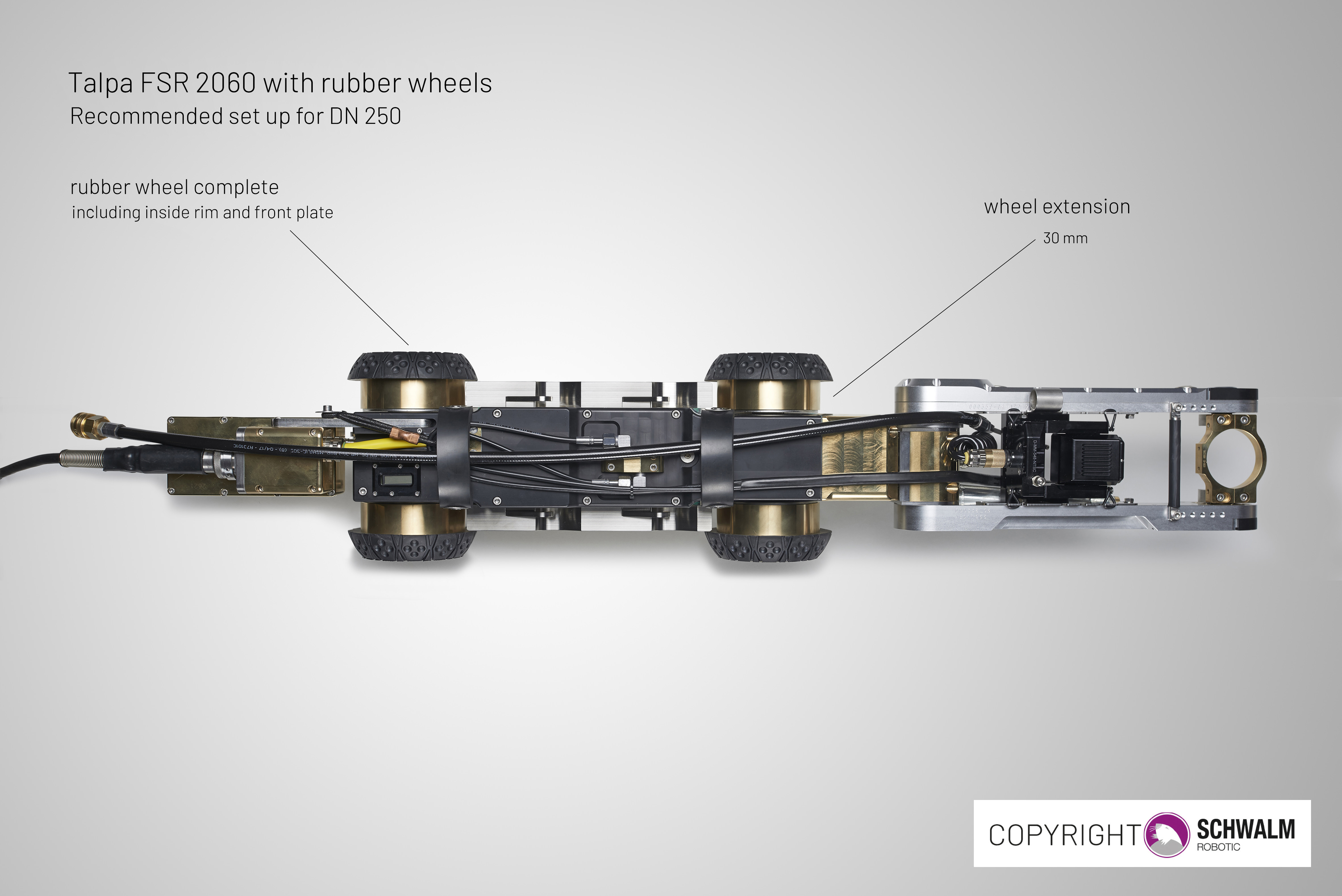

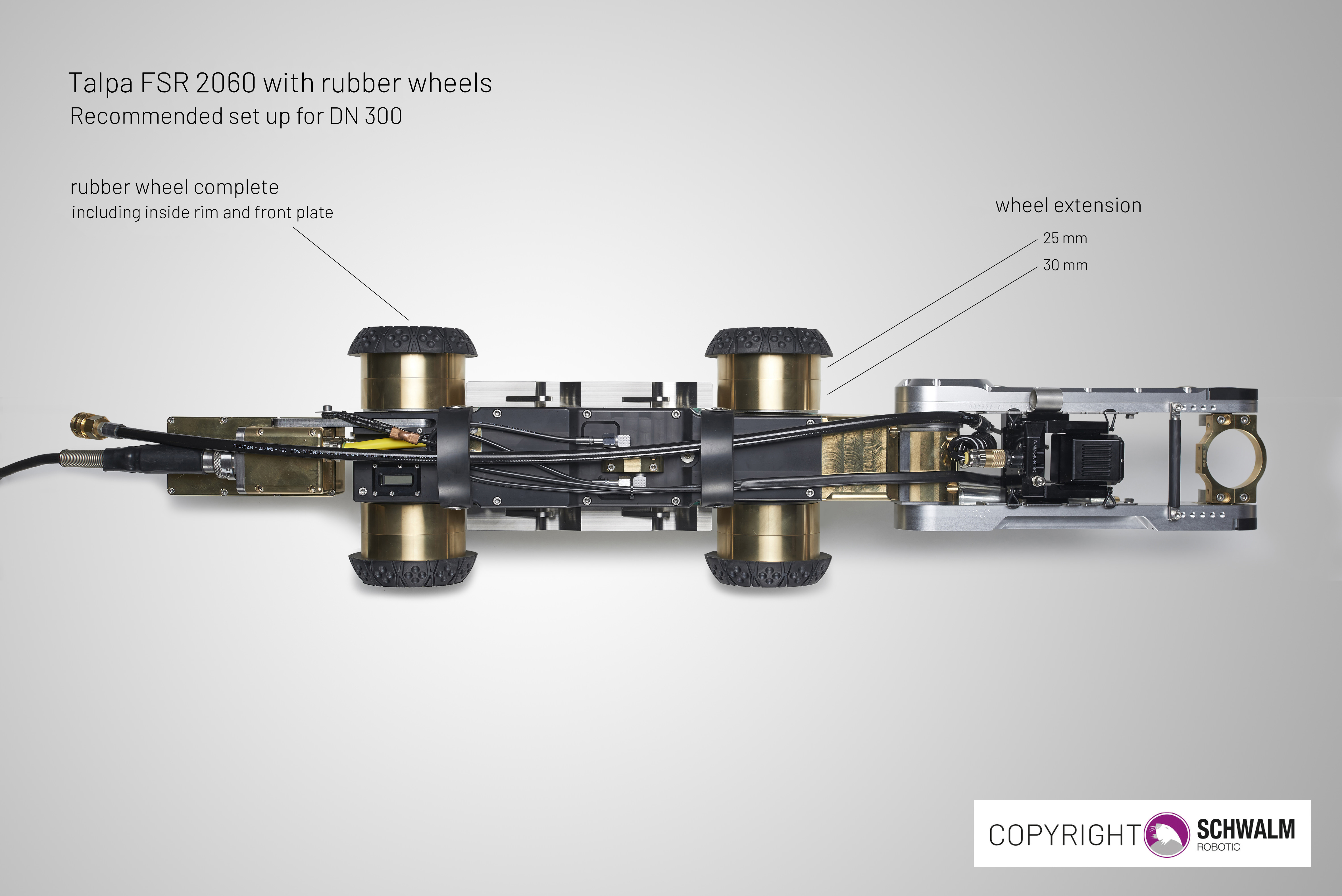

For pipe sizes from DN 200 (lined) to a maximum of DN 600

Talpa FSR 2060 has a standard design for pipes from DN 200 (lined) and can be equipped for pipe sizes to a maximum of DN 600 with the axle extenders and additional weights which can be combined with one another.

The robot is stable in the sewer pipe without requiring additional bracing or securing for the milling work. This is due to its own significant weight and its low center of gravity. Talpa FSR 2060 can tilt more than 45 degrees on its longitudinal axis without falling over.

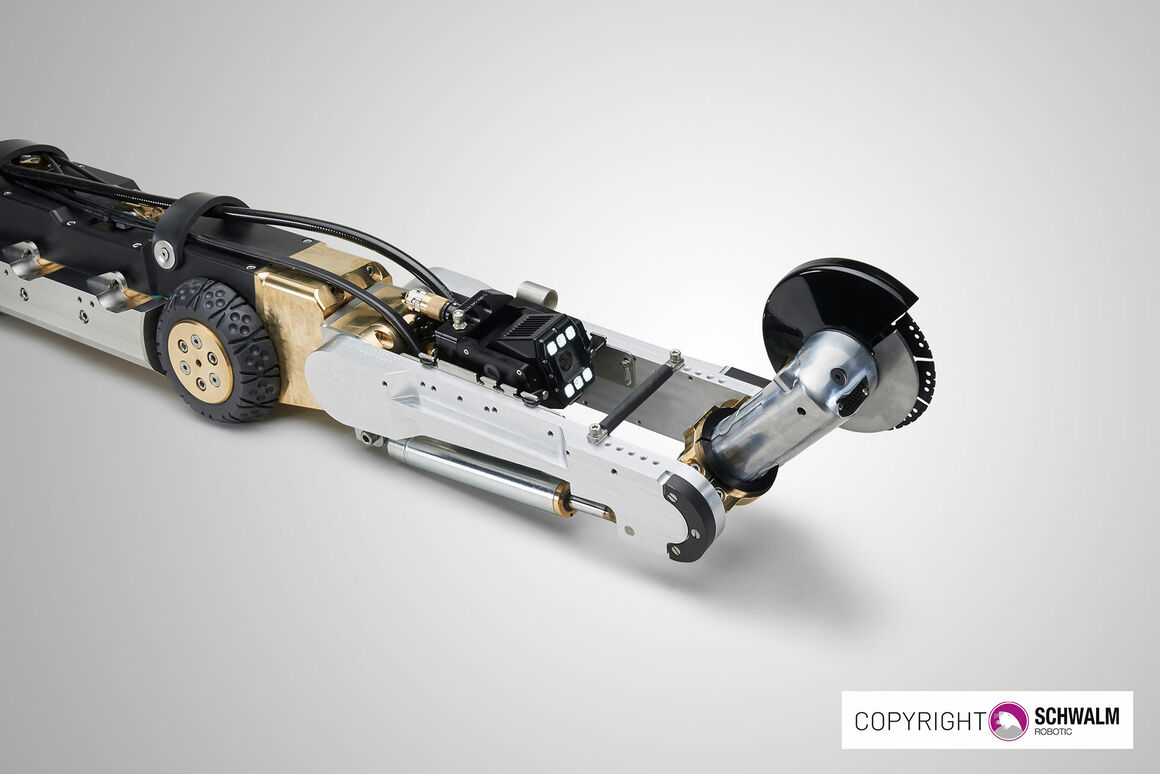

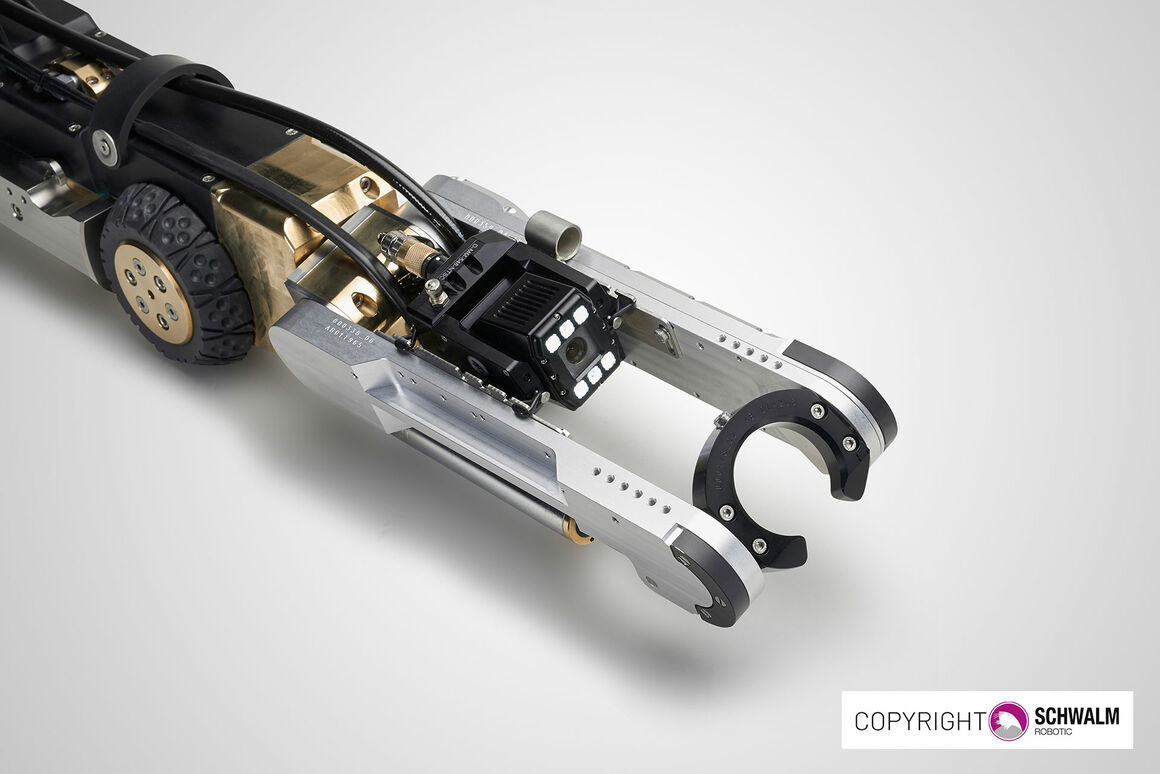

The robot has a high degree of free mobility. Its equipped tool can reach all areas to be processed in the sewer thanks to four degrees of freedom.

The degrees of freedom in detail are:

The camera mounted on the head can also be pivoted horizontally so that the view can easily be directed to the area being processed in the sewer or the mounted tool.

Pressurized interior space

To protect the interior space of the robot from the penetration of water, this is filled with air and subject to overpressure of 0.2 - 0.3 bar. With Talpa FSR 2060, this can be controlled or adjusted via valves in the center of the carriage and on the head using the air pump with pressure gage.

Multi-functional tooling mount

Various tools can be inserted into the tooling mount of Talpa FSR 2060 depending on the purpose of use. A milling stop (rod) can also be mounted into the center of the access arm to prevent the unintentional repelling of the tool.

To mount the hat liner, this serves to place the HutlinerPacker®, pipe sealing cushion (straight bubble) or to mount the chisel hammer, the tooling mount can easily be swapped via four screws.

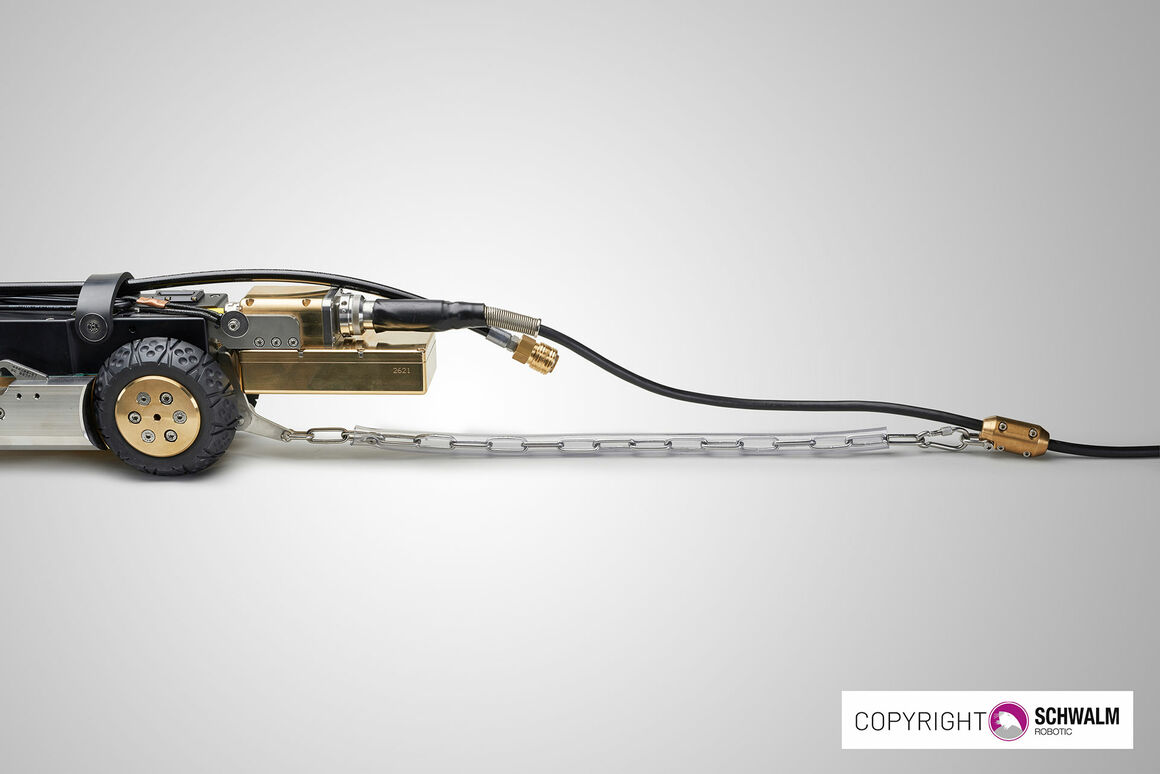

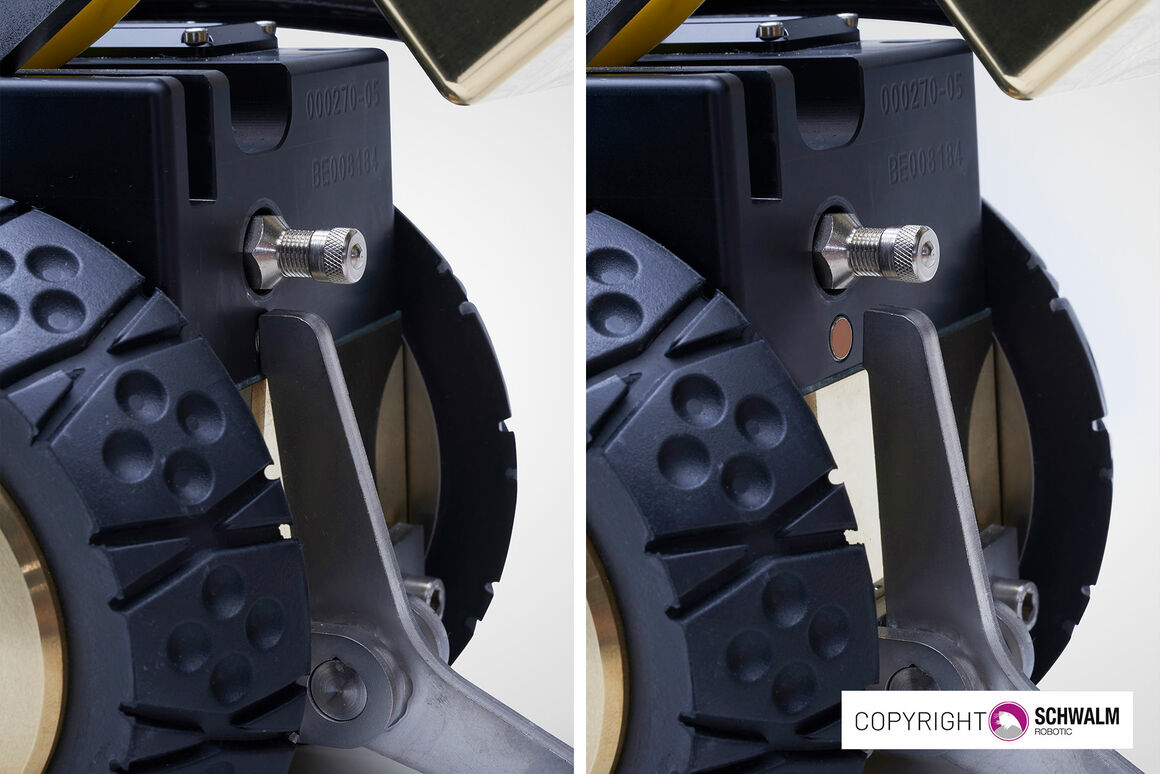

Strain relief / reverse driving control

To prevent unintentionally driving over the cable and the related damage when driving in reverse, the robot Talpa FSR 2060 has an integrated reverse driving control function. Here, the strain relief chain between the cable and reverse driving control rocker switch is tensioned. If the cable does not wind up fast enough during reverse driving, the rocker loses contact with the sensor and the reverse driving is prevented until the chain has tensioned itself again. This function can be switched on or off via the digital controls. The strain relief chain also protects the cable connector from tensile forces.

| Length without connector | 900 mm |

| Width | 150 mm |

| Height | 138 mm |

| Overall weight | 45 - 100 kg |

| For pipe diameters | DN 200 (lined) - DN 600 |

| Robot carriage drive | Four-wheel drive |

| Hydraulic pressure | 60 - 80 bar |

A camera model is available for Talpa FSR 2060

The following air motors are available for Talpa FSR 2060.

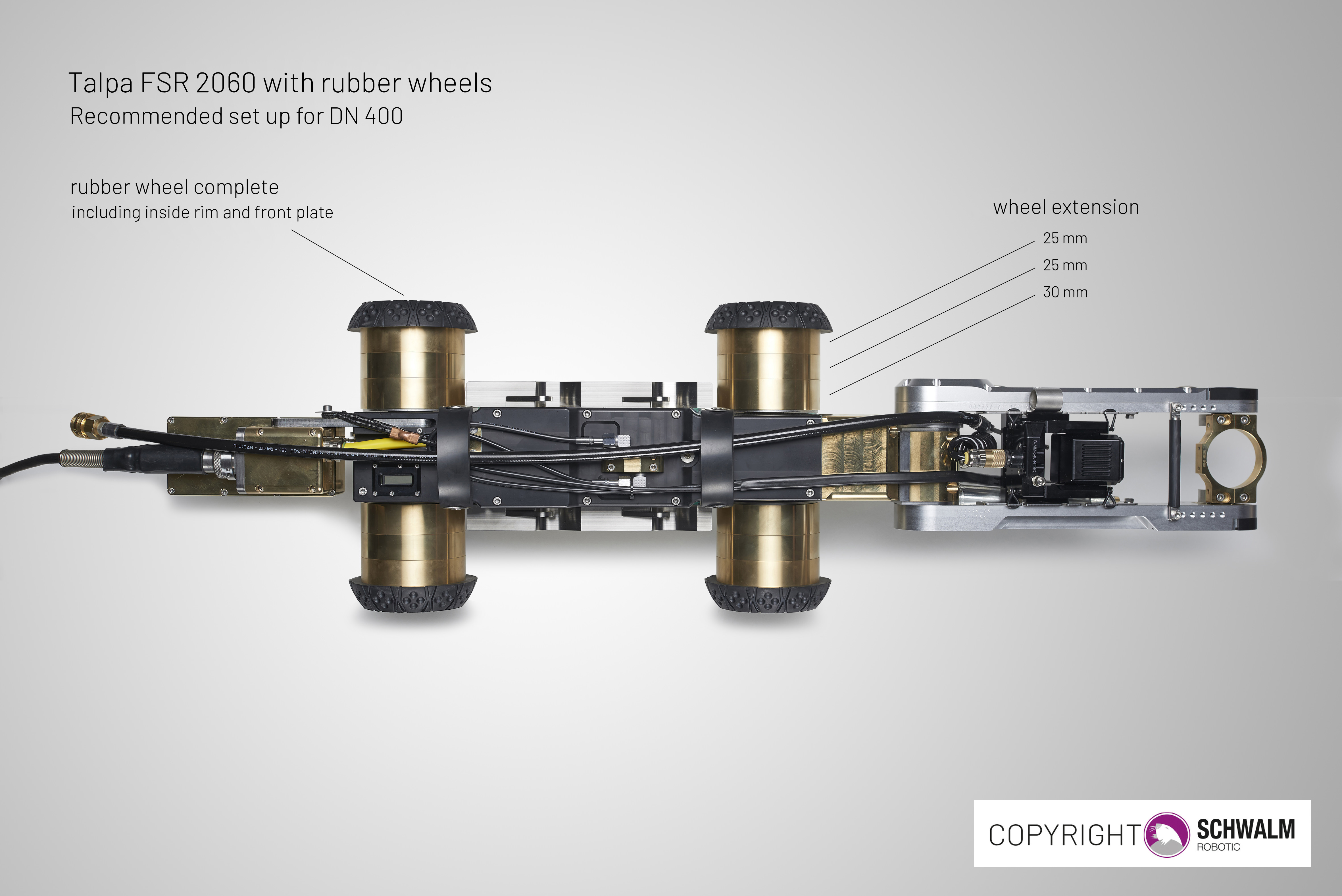

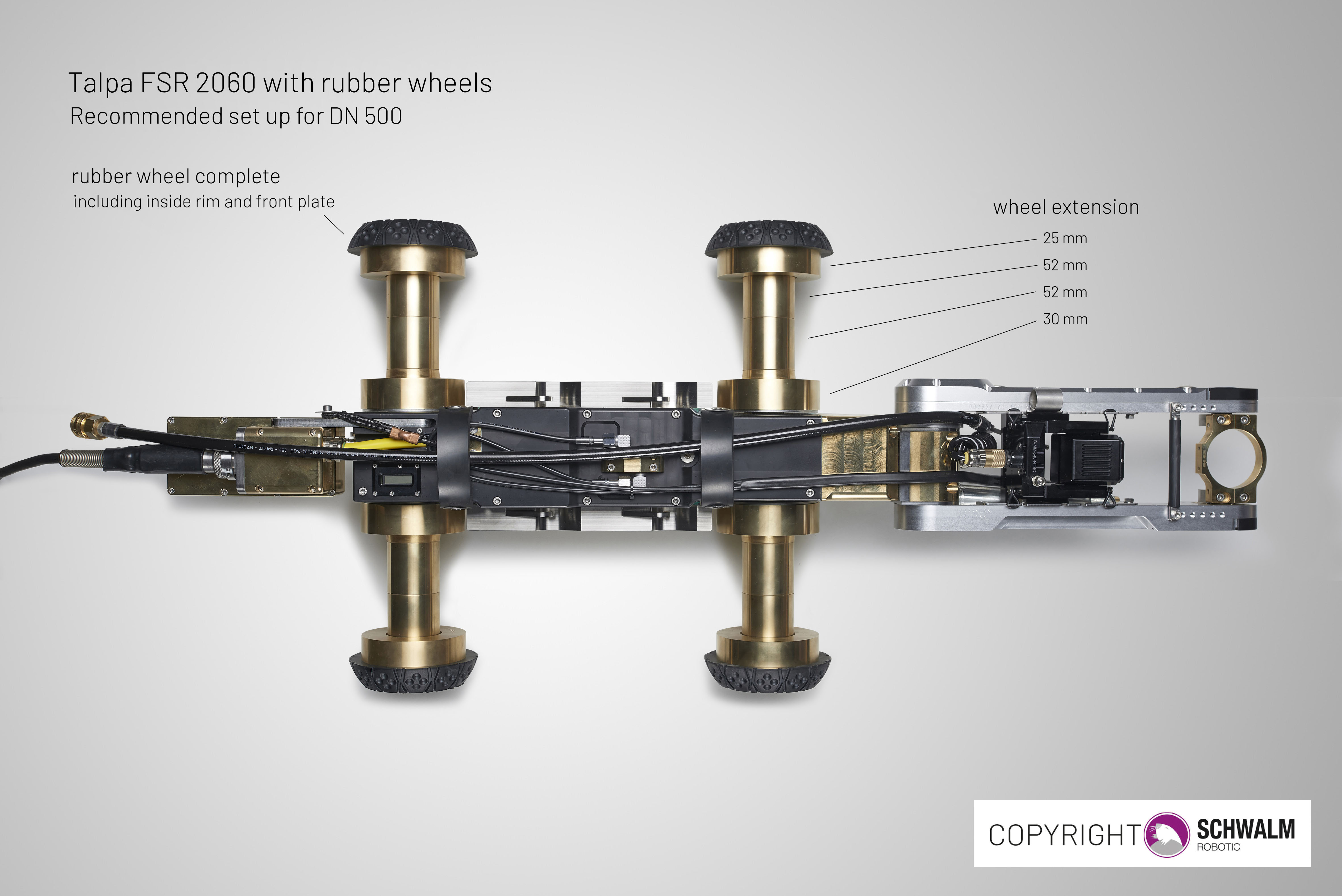

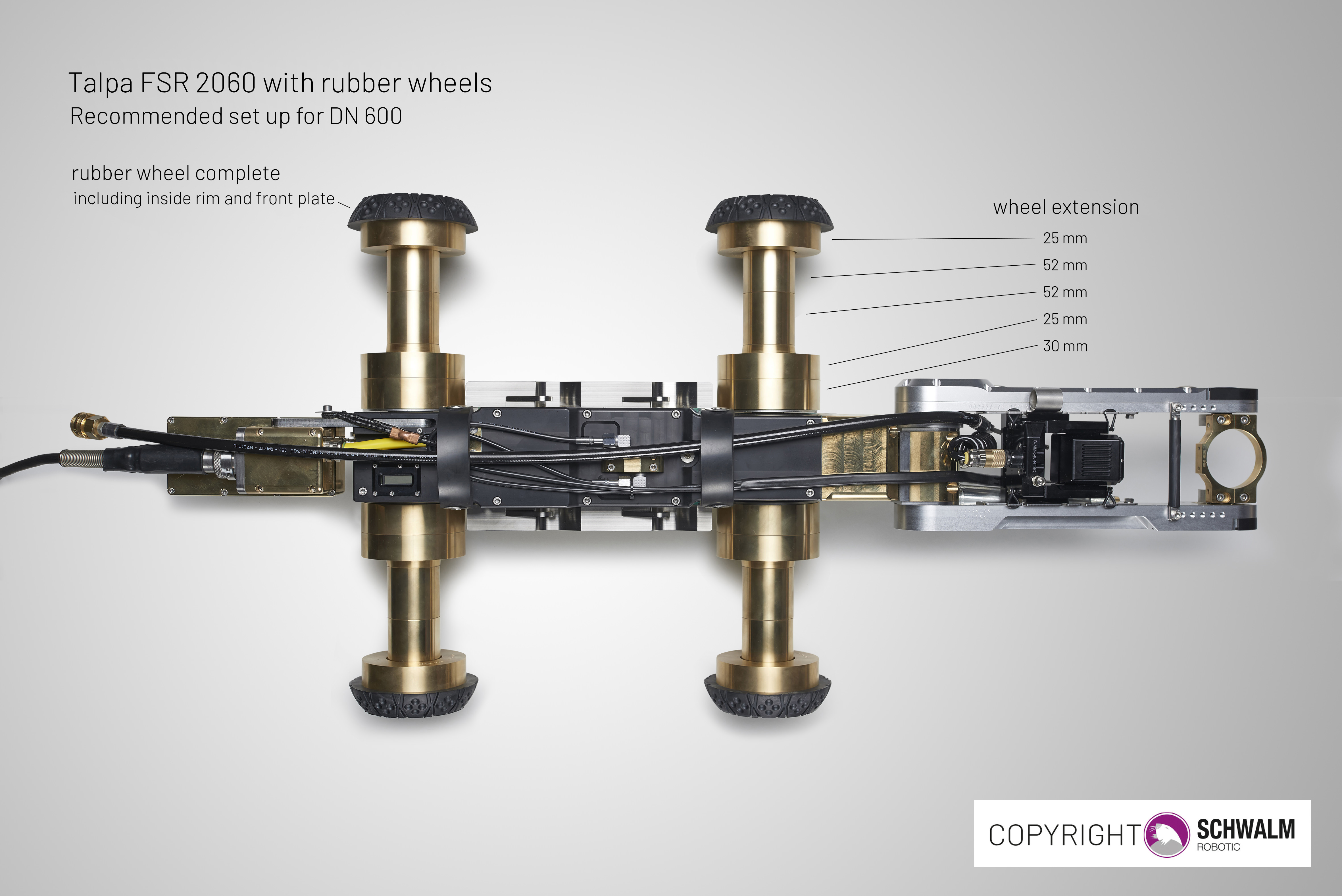

With the axle extender, the milling and sewer rehab robots can be used with the greatest pipe diameters in a way which causes low strain on their bearings. Thanks to the different axle extenders which can be combined with one another, the area of use of Talpa FSR 2060 can be expanded up to DN 600.

As standard, Talpa FSR 2060 is fitted with an axle extender set upon delivery.

The following models are available as wheels for Talpa FSR 2060.